General Installation

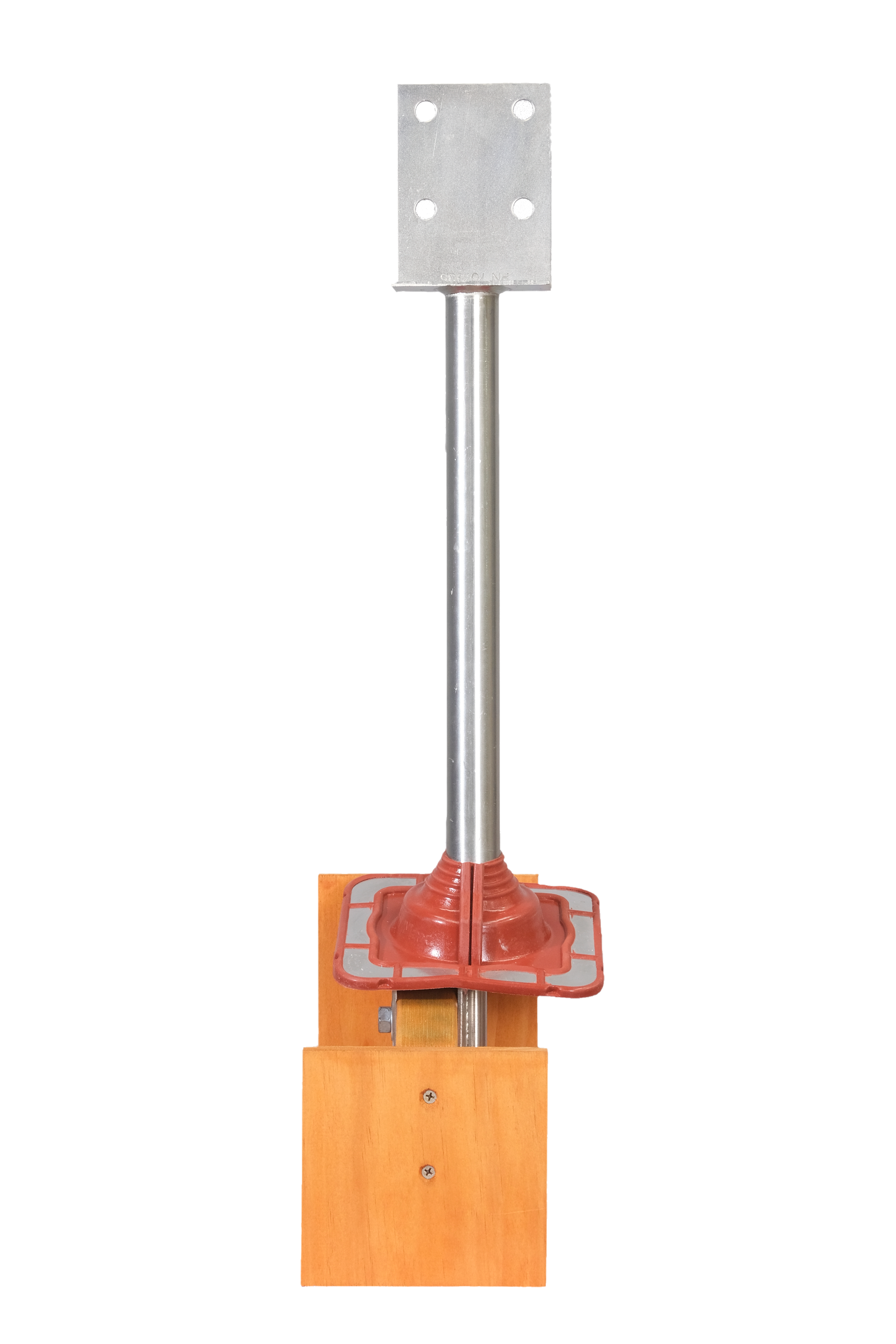

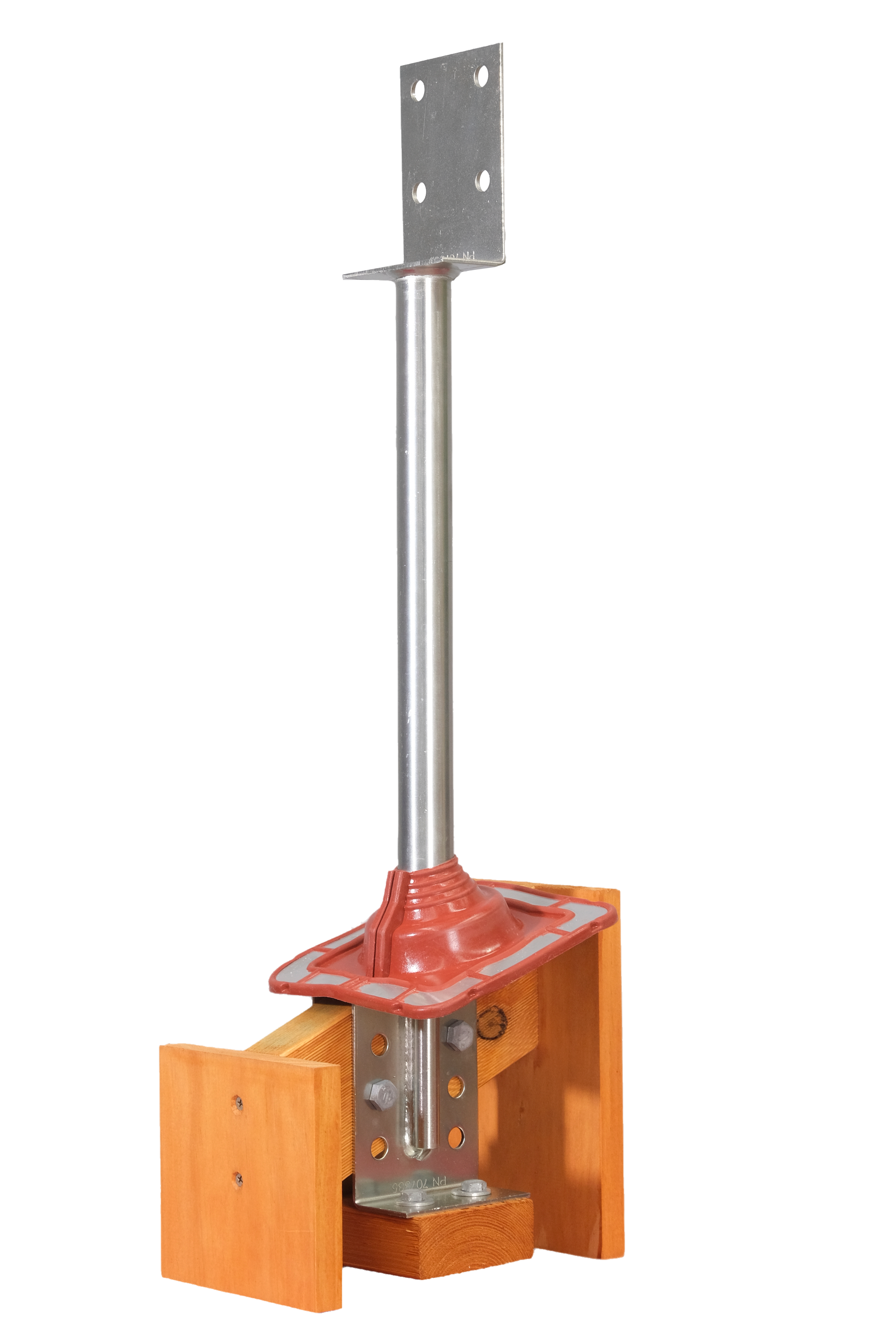

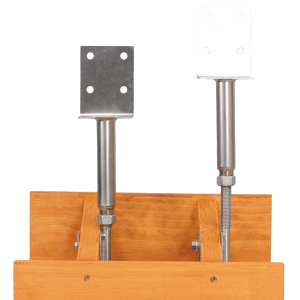

- Remove Roofing tiles or lift roof sheets to achieve an opening to fit the Roof

Extenda bracket.

- Bolt angle bracket to the threaded rod & backing plate to the selected rafter with 2 or 4 x M12 bolts. Secure the bracket to the top plate with 2-M10 coach screws through the two lower bottom holes.

- Replace roof tiles or roof sheet, cutting a hole to allow the threaded rod to penetrate the roof.

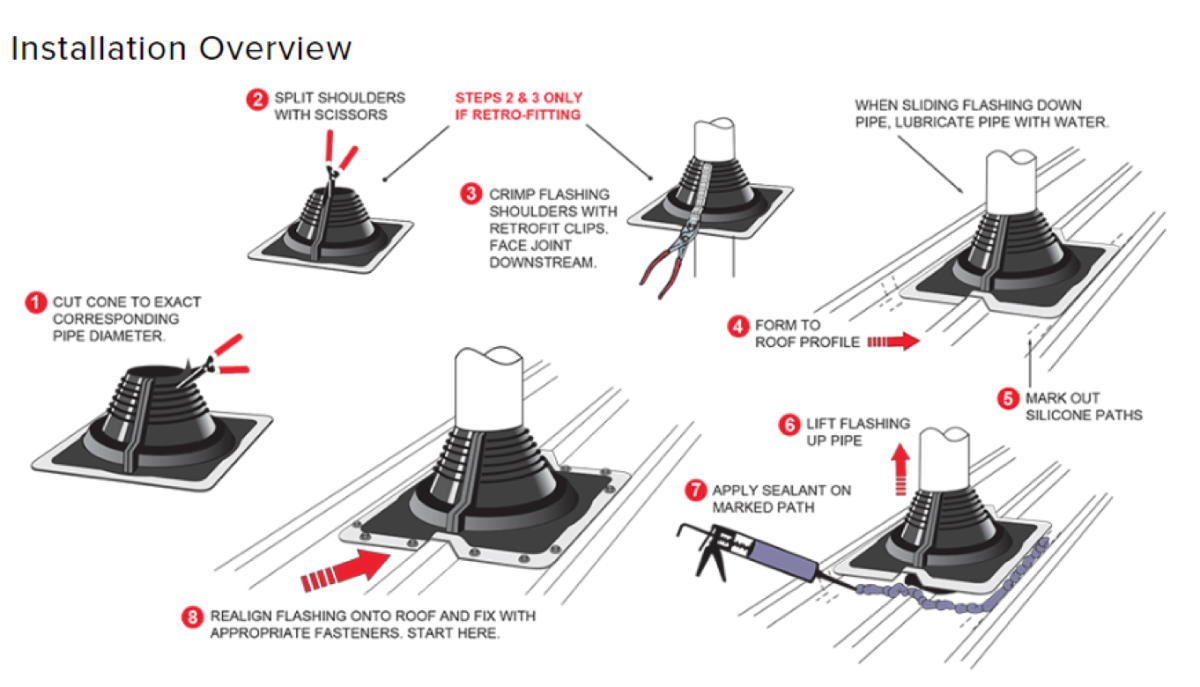

- The weather seal is fitted to the top bracket, top bracket is then wound down to the desired height and the lock nut tightened. Mark the position of the weather seal on the roofing. Slide the weather seal up to apply clear neutral cure silicone to the area marked, press & shape the weather seal into the roof profile and finish with a bead of silicone to the edges of the weather seal to complete the fitting.

Care Instructions

Brackets to be cleaned and inspected yearly and re-coated if required.

Note

Local Council or Shire approval may be required prior to construction. Engineer’s computations related to Roof Extenda products are available on the website. Roof Extenda accepts no responsibility for the type of construction undertaken.

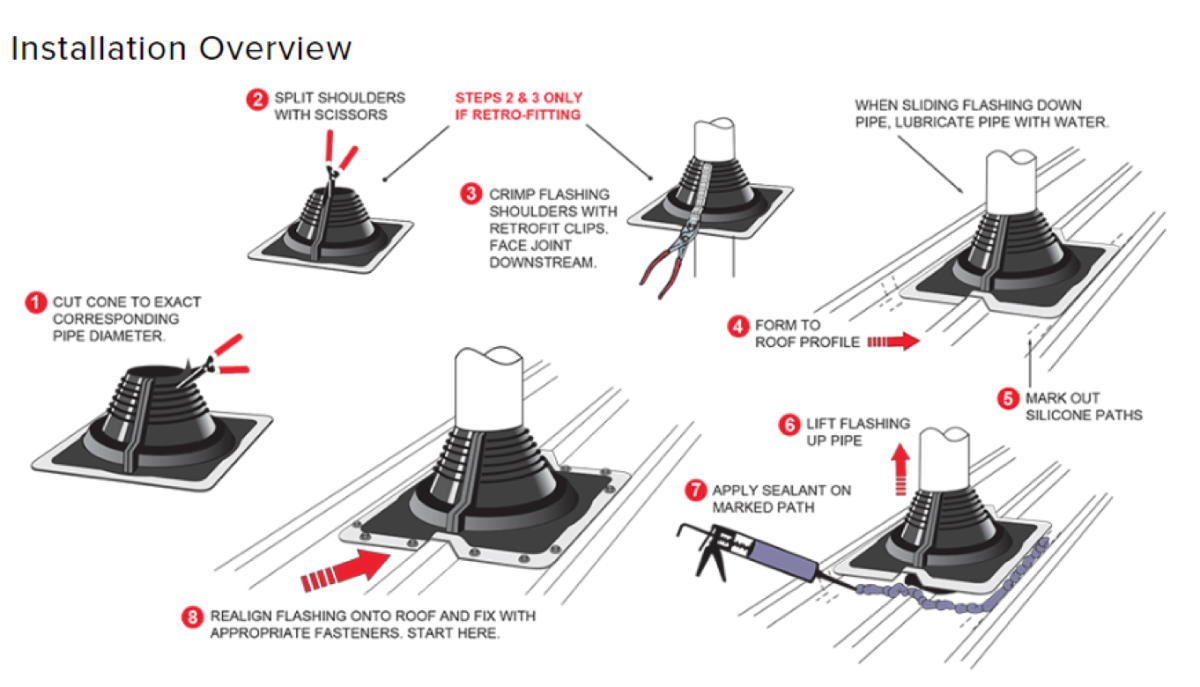

FlashRite Weather Seal

If using a FlashRite weather seal it is fitted to the top bracket, top bracket is then wound down to the desired height and the lock nut tightened. Mark the position of the FlashRite weather seal on the roofing. Slide the FlashRite weather seal up to apply clear neutral cure silicone inside the area marked, press the FlashRite weather seal into position and finish with a bead of silicone to the edges of the FlashRite weather seal to complete the fitting.

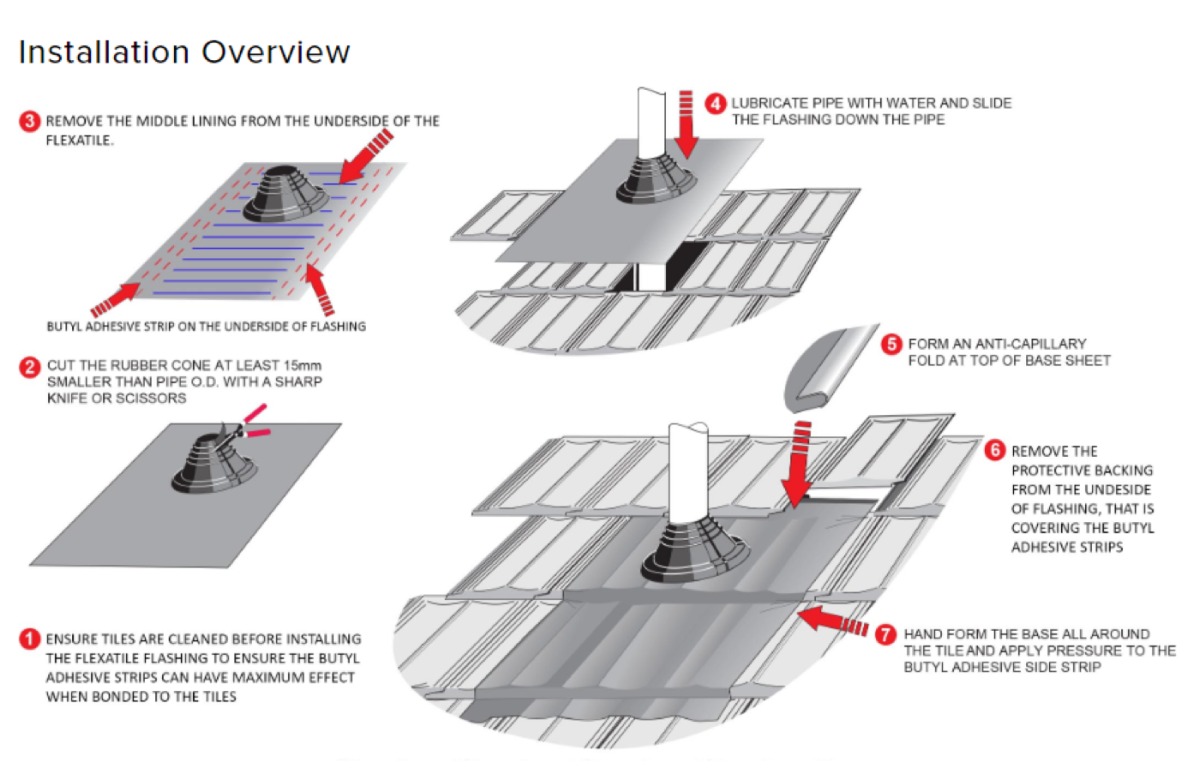

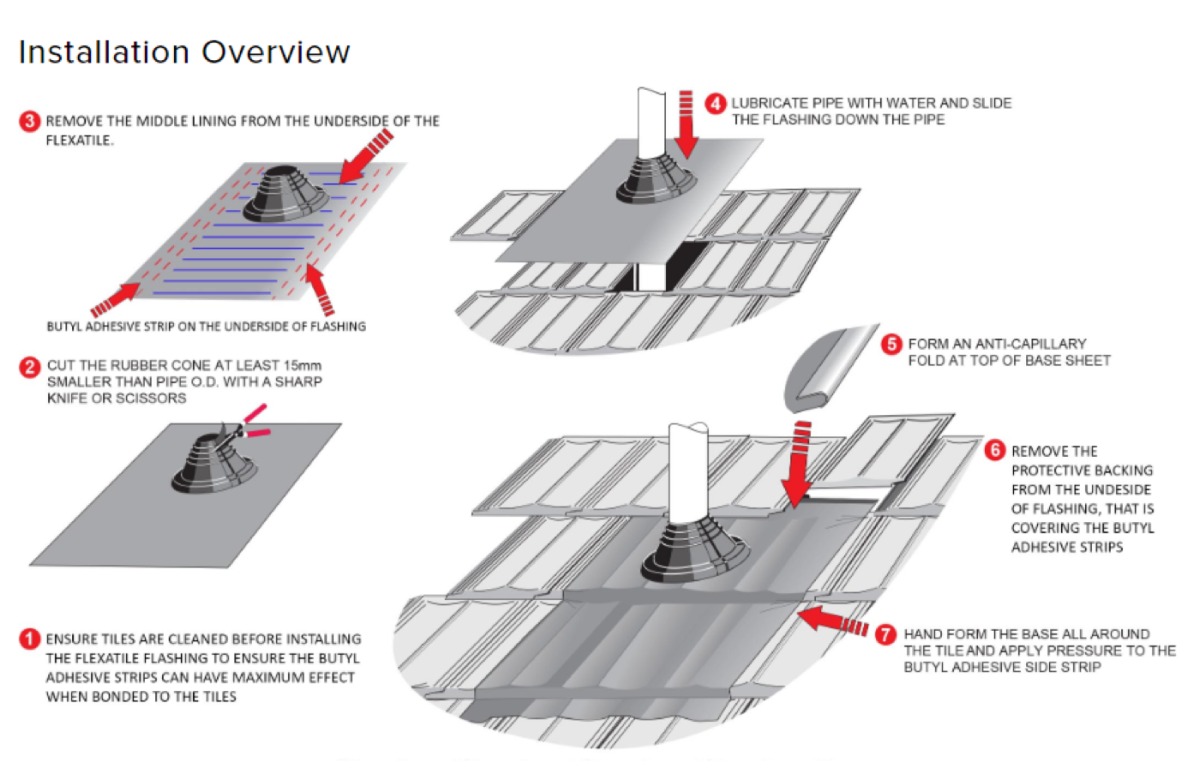

Flexatile

If using a flexatile, remove the middle lining from the underside of the flexatile. Cut the rubber cone at least 15mm smaller than the bracket OD with a sharp knife or scissors. Ensure tiles are cleaned before installation. Lubricate the bracket with water and slide the flashing down the bracket. Form an anti-capillary fold at top of base sheet. Remove the protective backing from the underside of the flashing, that is covering the butyl adhesive strips. Hand form the base all around the tile and apply pressure to the butyl adhesive side strip.

NOTE: Local council or shire approval may be required prior to construction. Roof Extenda accepts no responsibility for the type of construction undertaken.

Installation Guide S500 Roof Extenda Bracket

Need engineer computations for our extenda brackets?

Complete the online form here

Roof Extenda works with its manufacturers to produce a quality product. Roof Extenda has both electroplated mild steel & 316 marine grade stainless steel brackets available.

The zinc electroplated brackets have a top coating. Roof Extenda cannot provide any guarantees on the lifetime of the brackets and recommends the following:

- Roof Extenda recommends a qualified installer to seek advice from a coating manufacturer if brackets are to be coated prior to installation.

- Check brackets annually.

- Clean and coat if required with a cold galvanized paint which can be purchased at most hardware stores. This can be easily applied to the exposed surfaces of the brackets.

- If brackets show signs of corrosion they can be replaced by a builder.

If installing Roof Extenda brackets in highly corrosive areas we recommend the home owner considers using Roof Extenda’s 316 marine grade stainless steel brackets. Stainless steel brackets can still show signs of corrosion and should be checked annually.